Contents

The Role of Ergonomics in Musculoskeletal Disorders

29 May 2025

Musculoskeletal disorders (MSDs), sometimes referred to as ergonomic injuries, are serious, potentially life-changing injuries which affect thousands of people worldwide. In fact, according to the United States Bone and Joint Initiative (USBJI), MSDs are the leading cause of disability in adults. Additionally, the Bureau of Labor Statistics (BLS) in the United States found the private sector experienced over 975,000 MSD days away, restricted or transferred (DART) cases in 2021-2022, accounting for a third of all DART cases over the last few years. On a global scale, in 2019 the World Health Organization (WHO) identified data which showed approximately 1.71 billion people globally live with MSDs, a number that hasn't gotten better in recent years.

Even with a constant focus on implementing ergonomic best practices and reducing these types of incidents, how are we still experiencing so many MSDs?

The Importance of Ergonomics

Let’s begin by understanding what ergonomics are and how they play a role in organizational health and safety. The Occupational Safety and Health Administration (OSHA) defines ergonomics as “the science of fitting jobs to people.” Furthermore, the National Institute for Occupational Safety and Health (NIOSH) defines ergonomics as “the design of work tasks to best suit the capabilities of workers.” In short, the goal of ergonomics is to ensure the workplace is suited for a variety of workers, and workers are provided with a means of maintaining neutral work postures while conducting their daily tasks.

Despite the high number of people affected by poor ergonomics, work-related MSDs are preventable. To develop a deeper understanding of how we can better protect workers, let’s establish a baseline knowledge for identifying, assessing and resolving work-related MSDs.

What Is a Musculoskeletal Disorder?

MSDs are comprised of varied conditions affecting bones, connective tissues, joints and muscles. The WHO defines an MSD as “health problems of the muscles, tendons, bone skeleton, cartilage, ligaments and nerves.” To be considered an MSD by the BLS, the nature of the injury or illness must be one of the following:

-

Pinched nerve

-

Herniated disc

-

Meniscus tear

-

Sprains, strains or tears

-

Hernia (traumatic and nontraumatic)

-

Pain, swelling and numbness

-

Carpal tunnel syndrome

-

Raynaud’s syndrome

-

Or other musculoskeletal and/or connective tissue disease/disorder

When you consider the various types of injuries and/or illnesses which can occur, you can understand how MSDs are so prevalent. However, this doesn’t mean we have to accept them.

Back injuries are a prime example of this. Annually, there are over 1 million cases of serious back injuries in the workplace, leading to reduced productivity, decreased morale and increased insurance premiums. While we know how to minimize these types of incidents and how to maintain safe and healthy operations, we unfortunately don’t always follow those practices or even understand how to recognize ergonomic risk factors effectively.

Ergonomic Risk Factors

When ergonomic risk factors are present, there is greater danger of an MSD occurring. This highlights why it’s crucial for all employees to be able to recognize, reduce and/or eliminate these risks. Let’s review the six ergonomic risk factors:

-

Force: amount of effort made by muscles and subsequent pressure on the body to complete a job (i.e., pushing or pulling an object)

-

Contact stress: parts of body which come in contact with an outside element/object for extended periods of time (i.e., wrist resting on the side of a desk)

-

Vibration (whole-body and hand/arm): periodic back and forth motion/movement of an object (i.e., using a power tool or working near a power press)

-

Cold/extreme temperatures: working in extreme temperatures without being acclimatized and wearing proper PPE (i.e., working in extreme heat during the summer causing excessive fatigue and creating a need for more effort/force by the muscles)

-

Awkward posture: position of the body that deviates from its neutral position (i.e., a worker reaching over their head for extended periods of time)

-

Repetitive motion: tasks requiring the body to perform the same activity or motion repeatedly (i.e., a worker having to lift boxes repeatedly throughout the day or a given period)

Ergonomic risk factors and MSDs are not industry specific. They can adversely affect any worker across any industry, including nurses, factory workers, construction workers and office workers, with the only difference being the level (i.e., duration, frequency and severity) of risk exposure.

Understanding Controls

Implementing effective and efficient controls is critical to reducing the likelihood of an MSD occurring and further maintaining a safe and healthy working environment.

This is where the hierarchy of controls comes into play. There are five levels to the hierarchy, and they are ordered based on effectiveness.

-

Elimination: The physical removal of the hazard from the job.

-

Substitution: Replacing the hazard with a safer alternative.

-

Engineering: Controls reduce and/or prevent hazards from coming into contact with the workers.

-

Administrative: Controls change the way people work (i.e., limit the duration, frequency or severity of the hazard exposures).

-

Personal Protective Equipment (PPE): The equipment worn to minimize exposure to hazards. This is the last line of defense against hazards.

Implementing effective controls is just the beginning of establishing proactive actions to drive change. Instituting one or more of these controls will allow organizations to reduce hazardous situations to acceptable levels and in turn maintain tolerable failures. Moreover, continual monitoring of controls, hazards and work practices creates a stable foundation for workers and management alike to be proactive and in-tune with what is occurring in the workplace.

Ergonomics Program

Many organizations cover important ergonomic information in various modes, but it’s paramount to create, establish and implement an ergonomics program or policy that outlines everything we’ve discussed. A successful ergonomics program should include:

-

The basis of what ergonomics is and why it’s needed

-

What ergonomics risk factors are and how to recognize and prevent them

-

Hazard identification management

-

Creating and establishing job hazard analysis and controls

-

Employee awareness and training management

-

Medical management

-

Program management

-

Continued records management

This doesn’t mean it’s always required for organizations to have an official, standalone ergonomics program, but it is good practice to ensure aspects of an ergonomics program or policy are created and implemented within the overarching EHS program.

Utilizing Technology

EHS professionals play a crucial role in maintaining the health and safety of workers, workplaces and work processes. There are numerous organizational needs we must address, with processes in place to ensure safe operations are maintained. It’s critical we utilize proactive processes, tools and technology where available to learn and make better decisions for our workplaces.

For example, imagine utilizing digital tools that can assess how a worker lifts, transfers and lowers an object — a seemingly simple task that may actually pose significant risks upon closer analysis. Thus, having technology that can assess and monitor the job task allows real-time detection of hazardous scenarios and adverse movements. Instead of waiting for an incident to occur or conducting a post-incident investigation, technology lets us stay one step ahead of ergonomic risks.

More than just real-time assessments, technology can provide a simple method of quantifying various body analysis, including NIOSH revised lifting equation (RLE), rapid upper limb assessment (RULA) and rapid entire body assessment (REBA). Whereas ergonomists and EHS professionals have historically had to do these calculations by hand, technology now offers efficient tools which can calculate all this by just the click of a button.

Digital ergonomic tools also give the simplicity of creating, implementing and conducting ergonomic assessments. Software provides an opportunity for employees and EHS professionals to conduct ergonomic assessments via mobile devices or tablets anytime, anywhere.

Moving Forward

Ultimately, it’s up to organizations to make the appropriate changes to improve work-related MSDs. MSDs and other ergonomic-related injuries aren’t a new problem. The persistence of these incidents occurring means many organizations still aren’t tackling the root cause of ergonomic injuries.

Benjamin Franklin famously said, “An ounce of prevention is worth a pound of cure.” The more aware, prepared and trained we are, the better the outcomes. Improvement isn’t just about tools or processes — it’s about fostering a learning mindset and being open to new methods. Learn from past data, past actions and use those lessons to make better, more impactful decisions. In doing so, workplaces can drive meaningful change and improve human behavior.

Learn more about how our ergonomic assessment software can help keep your workforce safe.

Global EHS Specialist

Langdon Dement is a Global EHS Specialist at Evotix where he coaches organizations in general health and safety, ergonomics and change management with leadership. Dement is a Certified Safety Professional (CSP) and holds a master's in occupational health and safety from Murray State University. He is also a member of the American Society of Safety Professionals and the American Industrial Hygiene Association. He is renowned across the industry for his expertise in organizational EHS transitioning and development of EHS software solution tools. Dement is also the host of the popular health and safety podcast, “Two Bald Guys Talking Safety.”

RELATED BLOGS

How To Prepare for an EHS&S Solution Evaluation

5 August 2025 - Langdon Dement

When selecting EHS software, it’s important to choose a solution that aligns closely with your organization's unique processes. While many vendors offer tools that promise a range of benefits, the..

How To Prepare Your Workforce for Severe Weather Risks

3 April 2025 - Langdon Dement

Spring brings a much-needed change from a long, cold winter and the unforgiving weather conditions that accompany it. But as flowers bloom and temperatures rise, we also prepare for the arrival of..

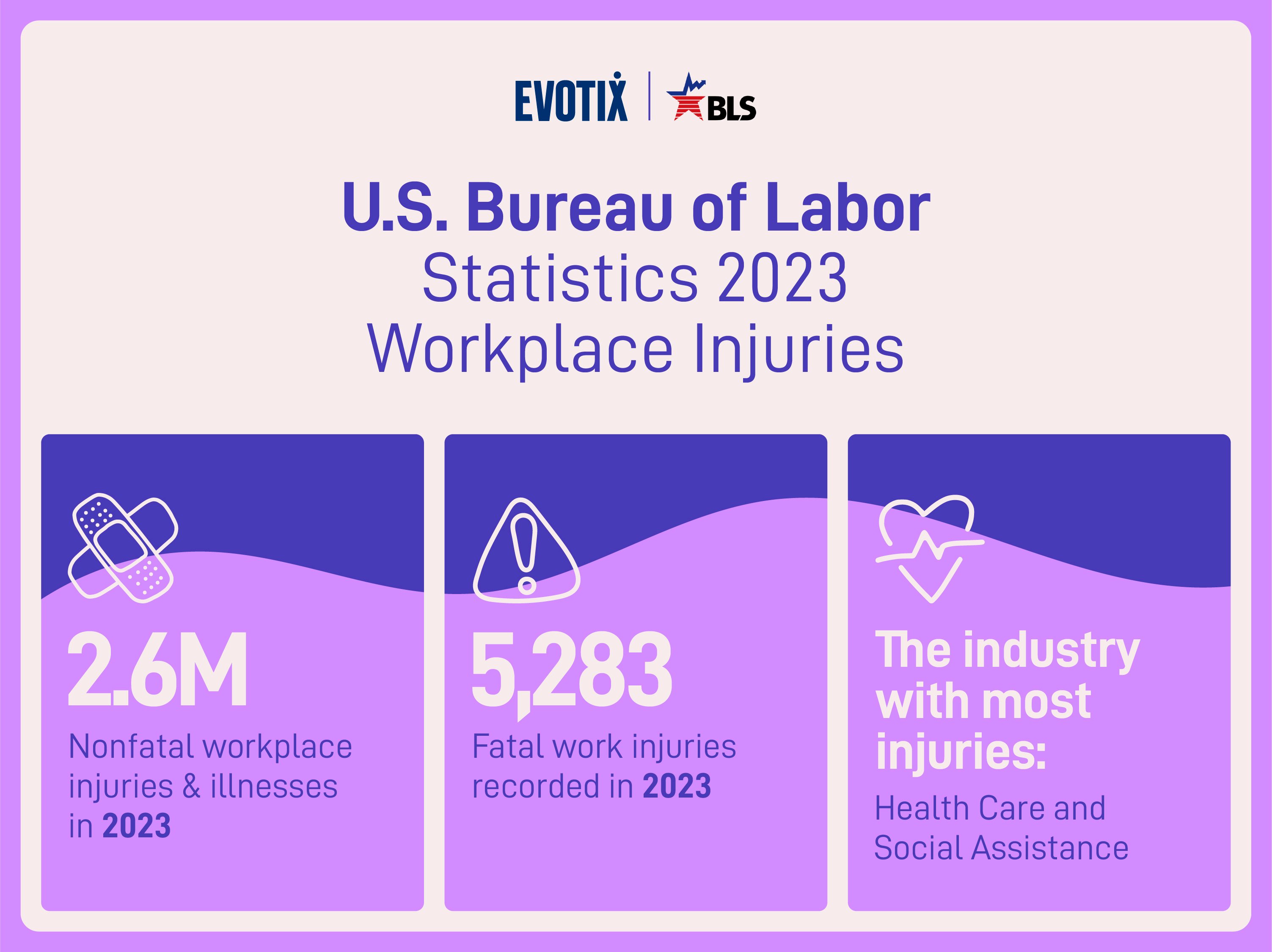

Bureau of Labor Statistics Releases 2023 Fatal and Nonfatal Injuries and Illnesses Report

16 January 2025 - Langdon Dement

The start of a new year offers the perfect opportunity for reflection. It's a chance to celebrate progress, assess past challenges and identify areas for improvement. As EHS professionals, we take..